Vibrating table specification

Features |

Specifications |

|---|---|

|

Max Weight

|

140 kg

|

|

Vibrating Range (Amplitude)

|

0-1 mm, 1-2 mm, 2-3 mm

|

|

Power Supply

|

230 Volts, A.C. Single Phase, 50 Cycles

|

|

Vibration per minute

|

2600 upto 3600

|

|

Table top

|

500 x 500 mm

|

|

Minimum Order Quantity

|

1 Piece

|

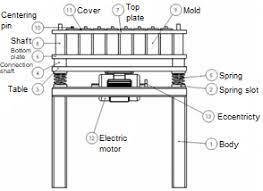

Product Description - Vibrating Table

What is Vibrating Table?

A vibrating table is an equipment that vibrates up and down. It is used for settling powders and similar items. The vibratory motion of the Vibrating Tables is particularly suited for settling granular to coarse materials. It is also very effective for handling various metal parts such as nuts, bolts and rivets. Usually, Vibrating Tables are of electromechanical construction and are available in multiple sizes and ratings. Motorised vibrating tables are available and are used for hefty applications

How to use Vibrating Table?

A vibrating table is used to aid the compaction of materials in containers, boxes, and bulk bags and cube moulds. The vibrating action helps materials and products nest closely and settle to reduce product volume to a minimum. This can minimise container size and therefore reduce the cost of transport.

How to Vibrating Table Designed?

Vibrating Table is designed to carry a load of 140 kg . The apparatus consists vibrating table motor fitted with a variable pitch pulley housed in a cabinet. The vibrations are imparted by means off-balance masses rotating on a shaft of a vibrator clamped to the underside of the table top.

The table top is 500 x 500 mm and has stops along its edges to prevent moulds from walking off the table during vibration . A crass arm adjustable on a vertical rod at the centre of the table is provided to hold the moulds while operating the between a maximum of 3600 vibrations down to 2600 vibration per minute. A speed regulation handle is provided for increasing or decreasing frequency. A switch is provided for starting the motor.

Features of Vibrating Table Machine

This vibrator has a strong vibrating unit on its inflexible table. It is utilized mostly to stack and defoam newly blended concrete for U-formed grooves, limit blocks, sections, PC plates, and other optional substantial items; the vibrator is additionally utilized underway lines for food sources, drugs, and different items to stack powder. The vibrator can likewise be utilized to advance infiltration in gently salted pickles and different staples and to desalt salted food fixings.

The rule of the vibrating table is to mount a workpiece-containing holder on a vibrating upper casing and to vibrate the actual compartment. An engineer of vibrators for development, we at EXEN Corporation partake in a long history and a rich track field in stacking newly blended concrete in auxiliary substantial item industrial facilities. We are additionally dedicated to table vibrators for modern hardware by exploiting our past encounters. (Items fabricated to arrange)

Note:

- Table top size : 750 x 750 mm 1000 x 1000 mm also available at an extra cost. Both models operates on 440 volts, A.C. Three Phase

Buy Vibrating Table

Vibrating Table Systems are proving to be cost effective as well as protean, because in numerous cases a client’s being dry cast, wet cast or packerhead- style rings and form outfit can be used.

Vibrating Table Systems can be as simple or as sophisticated as the client wishes. They can be located on the bottom, in a hole, or they can indeed be movable. Tables can be incorporated into the product system of an being dry cast machine, or they can stand alone. Tables can be supplied as a single or multiple station system.

Still, also a Vibrating Table System could be an ideal result, If you’ve been considering expanding your precast product line. Contact Construction Testing Equipment for further details on this protean, flexible system, and also imagine the possibilities!

Diagram of Vibrating Table