Features |

Specifications |

|---|---|

|

Material

|

Mild Steel

|

|

Usage/Application

|

Concrete Testing

|

|

Voltage

|

Hand operated

|

|

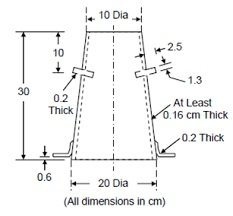

slump test apparatus size

|

Cone Size 200mm lower dia 100mm upper dia 300mm height

|

|

Height

|

Cone Ht 300 mm

|

|

slump cone test apparatus dimensions

|

Cone Lower 200mm upper 100mm

|

|

Mounting Type

|

On Foot

|

|

Minimum Order Quantity

|

1 Piece

|

Product Description - Slump Test Apparatus

What does a slump test measure?

Slump Cone Test Apparatus is used for the determination of the consistency of freshly mixed concrete, where the maximum size of the aggregate does not exceed 38 mm.

Standards: IS 7320 & BS 1881-102

Concrete Slump Test Apparatus

The concrete slump test is an on-the-spot test to determine the consistency as well as workability of fresh concrete. this test plays a vital role in ensuring immediate concrete quality in a construction project. it is used almost in every construction sites.

Apparatus of Slump Test is very simple and easy to handle. it also demands comparatively less equipment and can be done in a short period of time, these advantages of Slump Test Apparatus have made it very popular all over the world. in the slump test, workability of concrete is not measured directly. instead, consistency of concrete is measured which gives a general idea about the workability condition of concrete mix.

How does Slump Test Apparatus Work?

- Objective

The word ―workability or workable concrete signifies much wider and deeper meaning than the other terminology ―consistency often used loosely for workability. Consistency is a general term to indicate the degree of fluidity or the degree of mobility. The factors helping concrete to have more lubricating effect to reduce internal friction for helping easy compaction are : (a) Water Content (b) Mix Proportions (c) Size of Aggregates (d) Shape of Aggregates (e) Surface Texture of Aggregate (f) Grading of Aggregate (g) Use of Admixtures.

Slump Test Apparatus is the most commonly used method of measuring consistency of concrete which can be employed either in laboratory or at site of work. It is not a suitable method for very wet or very dry concrete. It does not measure all factors contributing to workability, nor it is always representative of the placeability of the concrete.

Slump Test Apparatus indicates the characteristic of concrete in addition to the slump value. If the concrete slumps evenly it is called true slump. If one half of the cone slides down, it is called shear slump. In case of a shear slump, the slump value is measured as the difference in height between the height of the mould and the average value of the subsidence.

- Procedure

If this test is being carried out in the field, the sample mixed concrete shall be obtained. In the case of concrete containing aggregate of maximum size more than 38 mm, the concrete shall be wet-sieved through one and half inch screen to exclude aggregate particles bigger than 38 mm.

The internal surface of the mould shall be thoroughly cleaned and freed from superfluous moisture and any set concrete before commencing the test. The mould shall be placed on a smooth, horizontal, rigid and non-absorbent surface, such as a carefully levelled metal plate, the mould being firmly held in place while it is being filled.

The mould shall be filled in four layers, each approximately one-quarter of the height of the mould. Each layer shall be tamped with twenty-five strokes of the rounded end of the tamping rod. The strokes shall be distributed in a uniform manner over the cross-section of the mould and for the second and subsequent layers shall penetrate into the underlying layer.

The bottom layer shall be tamped throughout its depth. After the top layer has been rodded, the concrete shall be struck off level with a trowel or the tamping rod, so that the mould is exactly filled.

After the top layer has been rodded, strike off the surface of the concrete by means of screeding and rolling motion of the tamping rod.

Any mortar which may have leaked out between the mould and the base plate shall be cleaned away. The mould shall be removed from the concrete immediately by raising it slowly and carefully in a vertical direction. This allows the concrete to subside and the slump shall be measured immediately by determining the difference between the height of the mould and that of the highest point of the specimen being tested.

The above operations shall be carried out at a place free from vibration or shock, and within a period of two minutes after sampling.

- Observation and Recording

The vertical difference between top of the mould and the displaced original center of the top surface of the specimen ………… mm

Workability | Compaction Factor | Slump (mm) |

Very Low | 0.78 | 0 – 25 |

Low | 0.85 | 25 – 50 |

Medium | 0.92 | 50 – 100 |

High | 0.95 | 100 – 175 |

Table 1 :Relation between Workability and Slump

- The pattern of slump is shown True Slump/Shear Slump/ Collapse Slump.

Type of Slump

The Slump Test Apparatus measured shall be recorded in terms of millimetres of subsidence of the specimen during the test. Any slump specimen which collapses or shears off laterally gives incorrect result and if this occurs the test shall be repeated with another sample. If, in the repeat test also, the specimen should shear, the slump shall be measured and the fact that the specimen sheared, shall be recorded.

slump test apparatus diagram

slump test apparatus uses

The Slump Test Apparatus measures the thickness of fresh concrete before it sets. It’s performed to check the plasticity of lately made concrete, and thus the ease with which concrete overflows. It can also be used as an index of an inaptly mixed batch. The test is popular due to the simplicity of outfit used and simple procedure. The Slump Test Apparatus is used to insure uniformity for different loads of concrete under field conditions.

slump test apparatus images