Specification of thickness gauge for aggregate

Features |

Specifications |

|---|---|

|

Brand

|

Lotustraders

|

|

Minimum Order Quantity

|

1 Piece

|

Product Description - Thickness Gauge

What is a Thickness gauge?

The thickness gauge is used to determine the flaking rate of aggregates. It consists of a frame with a sliding wall. The panel has grooves of various standard lengths and widths that are precisely cut.

The Thickness Gauge (flakiness Index gauge) measures the shape of aggregate particles used in road base courses or asphalt-concrete mixes. You can also determine application rates of aggregates and asphalt materials for floor sealants.

Standards: IS 2386 (PART 1) and BS 812

Thickness Gauge for Flakiness Index

The flaking index of aggregates is defined as the percentage by mass of particles (stones) whose minimum size (thickness) is less than three fifths of their average size.

Why is thickness gauge for aggregate done?

The aggregate flaking index test is performed on samples of coarse aggregates to estimate the shape of the aggregates. For cement concrete types and rough and bituminous base constructions, the presence of spongy and elongated aggregate particles is considered undesirable as they can cause inherent weakness with the possibility of collapse under heavy loads.

Therefore, an evaluation of the shape of the aggregate particles is necessary, mainly in terms of flaking and elongation.

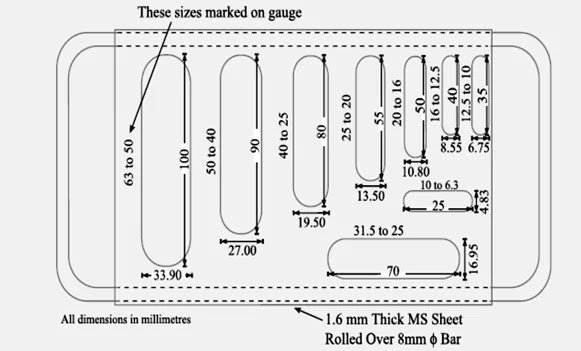

Thickness Gauge diagram / Flakiness Gauge Image

Equipment needed to test the flaking index of aggregates

The flaking index of an aggregate sample is determined by separating the spongy aggregate by sieving. The flaking index is expressed in weight as a percentage of the weight of the sample tested.

The flocculation index of the test aggregates does not apply to materials that pass through the 6.30 mm IS test sieve or are retained on the 63.00 mm IS test sieve.

- Gauge

- Climbing

- Stirrup

- Sieve

Procedure to calculate the test of thickness gauge for aggregate

The collective sample with the seven presented in table seven.

Collect enough aggregate to supply a minimum of 200 pieces of each fraction to be tested.

To separate the foams, the thickness of each fraction is measured with a thickness gauge of the model illustrated in Figure 1 or in bulk on elongated slotted sieves.

The groove width used on the Thickness gauge or screen must conform to the dimensions given in column 4 of the table for the appropriate material size.

Weight the total amount of foam passing through the calibrator to an accuracy of at least 0.1% of the test sample weight.

How to calculate gauge thickness:-

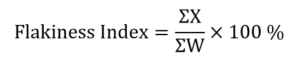

Aggregate Peeling Index Formula:

From where,

X = The weight of the material passing through the different thickness gauges and

W = Weight of aggregate that passes through specified sieves and is retained.

To perceive:-

The surface finish and shape of the aggregates affect the properties of fresh concrete more than the properties of hardened concrete. Rough, angled and oblong aggregates require more water to produce workable concrete than smooth, round and compact aggregates.

Therefore, the cement content must also be increased to maintain the water-cement (W/C) ratio. In general, flattened and elongated aggregate particles are avoided or limited to approximately 15% by weight of the total aggregate.