Features |

Specifications |

|---|---|

|

Usage/Application

|

For Cement Testing

|

|

Diameter

|

30 cm

|

|

Height of the Mould

|

90mm

|

|

Conical Mould Material

|

Brass

|

|

Conical Mould Diameter

|

65mm

|

|

Minimum Order Quantity

|

1 Unit

|

Product Description - Flow Table

What is Flow Table

As suggested by the name itself, this test determines the workability of concrete / cement by examining the flow properties of the concrete. To determine the flowability of the concrete, a flow chart test is performed on the concrete. It also indicates the workability or consistency of the concrete.

The cement flow table test also determines the quality of the concrete in terms of consistency, cohesion and tendency to segregate.

As there are two methods for determining the yield value of concrete, one is obsolete. Here we explain the new flowchart testing method.

The flow table apparatus test or flow test is a method of determining the consistency of fresh cement /concrete. A flowchart test is also used to determine the transportable moisture limit of solid bulk products. It is mainly used to test concrete that is too fluid (workable) to measure with the slump test, as the concrete will not hold its shape when the cone is removed.

Procedure of flow table test:

- Prepare the concrete / cement according to the mix design and place the flow table on a horizontal surface.

- Remove dust or other granular material from the flow plate and spray with water with one hand.

- Now place the metal cone in the middle of the flow table and stand on it.

- Pour the freshly mixed concrete into the two-layer mold; Each layer must be compacted 25 times with a compaction rod. Once the last layer has been deposited, the concrete that overflows into the cone is leveled with a trowel.

- Slowly lift the formwork vertically, allowing the concrete to stand unsupported.

- The flow table is raised and lowered to a height of 12.5 mm. The same thing is repeated 15 times in 15 seconds.

- Measure the diameter of the length of concrete with a horizontal and vertical centimeter scale. The arithmetic mean of the two diameters must be the flow in millimeters.

The formula for the flow value: (D1+D2)/2

Flow Table Size

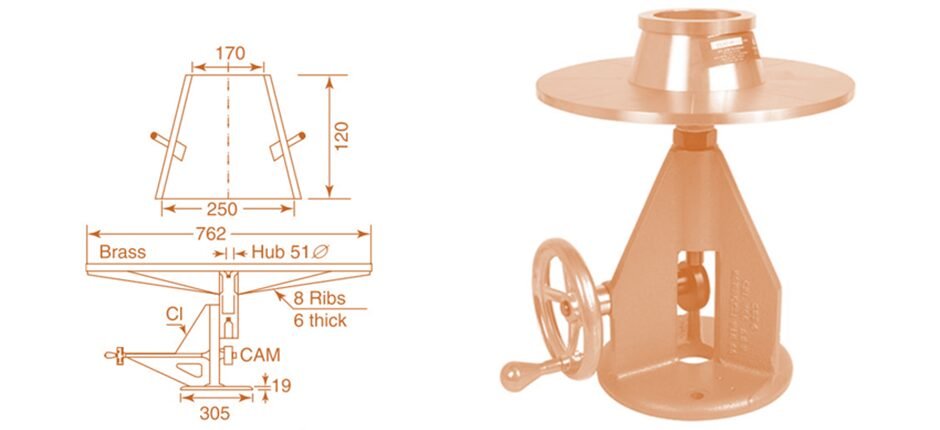

The flow table device consists of a polished steel plate 30 cm in diameter with 3 engraved annular circles of 7, 11 and 19 cm in diameter. The table top is designed for 12.5mm free fall per cam. Comes complete with a tapered brass die 65mm internal diameter. at the base and 40 mm i.d. above mold height 90 mm.

Flow Table Test IS Code: IS 5512 and BS 4551-1

Flow Table Test Diagram